Surface mount technology

Surface mount technology is the most common and effective way of populating the printed circuit board with various devices and components, also called chips.

SMD assembly significantly differs from through hole technology used previously.

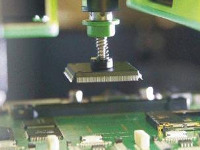

This way of assemly, provided by our personnel, features following main stages: during the first one solder paste is applied to PCS pads. The next one includes placing the components, this stage can be performed manually or by pick-and-place machines. Then the boards are conveyed into the reflow soldering oven, and afterwards they are covered with the compound protecting the board from mechanical damage.

The main adventages of this technology are lower cost of the resulting device, simpler and faster automated assembly and the option of placing smaller components on both sides of the circuit board with much higher density, also SMT does not decrease the quality of production.